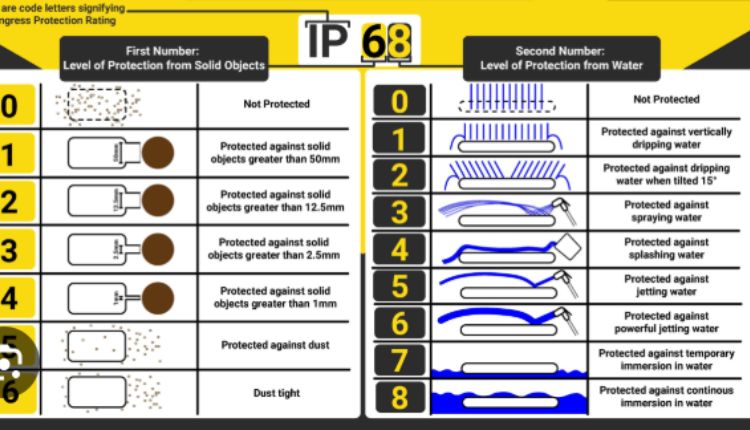

Each rating is represented by two letters IP and two digits, the first indicating protection from solid objects such as hands and tools, and the second indicating protection against water from dripping, spraying, splashing or immersion.

Ingress Protection Ip Rating

Ingress protection, sometimes referred to as an IP rating, is a standard that indicates the level of resistance an enclosure or case offers to foreign substances. In contrast to more vague marketing terms such as ‘waterproof’ or ‘dustproof,’ an IP rating offers a much clearer picture of how well a product will withstand various hazards and scenarios.

The standard is based on the European standard EN 60529. IP ratings consist of two digits, with an optional letter. The first digit indicates the degree of protection from solid particles, while the second digit identifies the degree of protection against liquid ingress. A number can also be replaced by X, indicating that the enclosure is not rated for that particular category.

A good understanding of IP ratings can help you select the right hardware for your needs and applications. For example, if you work in the food industry and need your equipment to withstand frequent and intense washdowns, it is important to choose hardware that has an IP69K rating. This rating is extremely robust and offers protection against both dust ingress and high-temperature, high-pressure jets of water from multiple directions at close range.

OnLogic’s Tacton panel PC series, for instance, is available in both IP69K and IP66 ratings. Whichever you choose, you can be sure that your hardware will withstand the harsh conditions of your environment and will function as intended.

When selecting a solution, it is important to ensure that your equipment will meet the requirements of your environment and application. Failure to do so could result in damage to your equipment, which can cost you time and money while compromising on the quality of your work. By taking the time to understand your IP rating requirements and by choosing a solution that meets those specifications, you can be confident that your hardware will provide the performance and reliability you need. To discuss how an ip rated solution can help your business, get in touch with our technical sales team today. Your details will be treated with care and will never be shared with third parties.

Dust Protection Ip Rating

Many people fear airborne particles as dangerous as asbestos or silica, but other kinds of dust are often overlooked. Combustible dust fires and explosions can happen in the blink of an eye and ruin people’s lives. For example, a flash fire in a food processing facility can spread rapidly and destroy the entire plant. Fortunately, these incidents can be prevented with proper planning and safety measures. For instance, employees can wear disposable protective clothing such as those made by International Enviroguard to prevent harmful dust from reaching sensitive equipment and triggering an incident.

To help ensure that the right kind of dust protection is in place, workers should study the characteristics of the dust they work with. For example, the particle size, material composition, moisture content, and ignitability will determine how flammable it is. Additionally, a risk assessment should be conducted to identify the presence of any potential hazard. This should also include a review of existing safety measures and controls such as dust collection systems, explosion venting, anti static, and personal protective equipment.

As far as IP ratings are concerned, the first digit in an IP rating represents how well the product or enclosure resists penetration by solid objects. The second digit reflects how watertight the product is. The IP rating system was developed in 1976 to address issues with electric and electronic devices that deteriorated or failed when water or dust entered their enclosures or housings. Today, the rating system is used by manufacturers to prove that their products comply with the global standard and can be trusted to function in a variety of environments.

For example, an enclosure with an IP rating of 6 offers excellent protection against dust intrusion and is almost impenetrable by solids. This level of protection is suitable for a wide range of industrial and commercial environments where dust is present but not overwhelming. It’s also a great choice for residential garages and light workshops where it is acceptable that some dust may infiltrate an enclosure without disrupting its normal operation.

The right kind of dust protection is essential for protecting your workers and equipment, so choosing the best IP rating involves balancing your environment’s unique challenges with the protective features of each product. To find out more, contact a Select representative who can help you make the right choice.

Water Protection Ip Rating

When choosing fixtures for use in wet environments, it’s important to consider IP ratings. These standards help ensure the device will be protected against the intrusion of solids and liquids. An IP rating has two numbers, the first indicating levels of protection from solid objects and the second indicating levels of protection from liquids. Each number is described in a table and the higher the number, the more protection the device has against solids and liquids.

In addition to being safe against dust, an IP65-rated device is safeguarded against low-pressure jets of water from all directions. This means that it can withstand occasional splashes of water and even short periods of immersion. However, it does not guarantee protection against full submersion or prolonged exposure to water.

While devices with the IP65 rating are not completely waterproof, they do offer a high level of protection. They can withstand brief immersion in water up to one meter deep for 30 minutes without suffering any adverse effects. This makes them suitable for use in places that require frequent washdowns, such as food and beverage processing plants.

The difference between an IP65-rated device and an IP67-rated device lies in their ability to protect against dust and water jets. IP67 devices can withstand both dust and low-pressure water sprays, making them ideal for scenarios where splashes are common. In contrast, an IP69K-rated device is able to resist both dust and direct high-pressure water jets at a specified temperature. This rating is typically seen on devices used in industrial machinery, such as motors and gear motors, where they are regularly exposed to dirt, fertilizers and frequent wash-downs at high pressure.

When purchasing a product with an IP rating, be sure to check its specification sheet for information on the specific tests it has passed. Beware of manufacturers who claim to have products that are waterproof without performing the necessary tests. The term waterproof refers to a device’s ability to stop water from entering, while the term water resistant describes a device that can withstand limited amounts of exposure to water and still function normally.

Chemical Resistance Ip Rating

The IP rating system (also known as the Ingress Protection Code or International Protection Rating) defines the level of protection a device enclosure has against ingress from solid foreign objects and liquids. A product’s IP rating is indicated by the letters “IP” followed by two digits, the higher the number the more protection it has. If the number is replaced by a “X”, it indicates that the enclosure has not been tested to that specification.

The first digit in an IP rating indicates the level of protection from solid foreign particles such as tools and dust, with numbers ranging from 0 to 6. The second digit refers to the level of water resistance, with numbers ranging from 0 to 9. Water resistance testing is done with an oscillating spray head that looks like a garden sprinkler, or manually using a handheld showerhead. The enclosure is exposed to the spray or jet for at least three minutes, depending on the rated IP level.

An important thing to note when looking at an IP rating is that manufacturers only publicly rate devices to what they have actually been tested against. This means that even though a device may have a high IP69K rating, it may not be suitable for use in a refrigerated environment where condensation can occur.

More Words

For industrial coding lines that must operate in environments with harsh cleaning procedures, an IP69K rating is the highest protection possible. This is because products with this rating are designed to withstand both dust and directed water jets of high temperature and pressure. This is especially critical for industries such as food processing where equipment must be sanitized regularly to maintain hygiene and cleanliness standards.